1. Introduction

A complete 5 cm2 alkaline anion exchange membrane water electrolyzer.

The electrolyzer is designed to be run with 1 M KOH flowing on the anode and cathode as described in Zengcai Liu et al. “The effect of membrane on an alkaline water electrolyzer” https://doi.org/10.1016/j.ijhydene.2017.10.050

2. Components

- corrosion resistant 5 cm2 anode and cathode flow fields

- an MEA with base metal catalysts

- metal gas diffusion layers

- o-ring seals, and Teflon gasketing

- No heaters or cabling included

Note: The electrolyzer is built when the order is received. It generally takes up to 2 weeks to build and test the unit before shipment.

***Buyer represents and warrants that all uses of Product will be for Buyer's own use, which means, in particular, that Buyer will not sell, distribute, or transfer Product, whether directly or indirectly, to any class of trade (each a Product Diversion ). Any Product Diversion shall be considered a material breach of this Purchase Contract. The Products contain chemical substances not on the Toxic Substances Control Act (TSCA ) inventory. Samples may be hazardous. Buyer represents and warrants that it will only use the samples for research and development purposes under the supervision of a technically qualified individual.

| Accessories | ||||

| AEM | ||||

| Ionomer | Nafion D2021 | Fumion FAA-3 5wt% in ethanol | ||

| GDL |

DM Ni fiber paper 福优塞尔® Ni fiber paper |

DM SS fiber paper 福优塞尔®SSFP-A62L SS fiber paper | CP-A210R raw carbon paper CP-A330R raw carbon paper CP-A400R raw carbon paper CP-H450R raw carbon paper CP-H850R raw carbon paper | 福优塞尔® Ti fiber paper 福优塞尔® Ti screen 福优塞尔® Platinized Ti fiber paper 福优塞尔®Platinized Ti screen |

| Anode GDE |  DM NiFeOx-SS fiber paper 福优塞尔® E100H NiFeOx-SS fiber paper with hydrophilic interface 福优塞尔® E100T NiFeOx-SS fiber paper with hydrophobic interface | 福优塞尔® E110H CoFeOx-SS fiber paper with hydrophilic interface 福优塞尔® E110T CoFeOx-SS fiber paper with hydrophobic interface | DM IrO2-carbon paper 福优塞尔® E300 IrO2-carbon paper 福优塞尔® E300T IrO2-carbon paper with hydrophobic interface 福优塞尔® E300H IrO2-carbon paper with hydrophilic interface | 福优塞尔® E304T IrO2-Ti fiber paper with hydrophobic interface 福优塞尔® E304H IrO2-Ti fiber paper with hydrophilic interface 福优塞尔® E305T IrO2-Platinized Ti fiber paper with hydrophobic interface 福优塞尔® E305H IrO2-Platinized Ti fiber paper with hydrophilic interface |

福优塞尔® E309 IrO2/Ti fiber paper 福优塞尔® E310 IrO2/Platinized Ti fiber paper 福优塞尔® E311 Pt-IrO2/Platinized Ti fiber paper | 福优塞尔® E314 IrO2/Ti screen 福优塞尔® E315 IrO2/Platinized Ti screen 福优塞尔® E316 Pt-IrO2/Platinized Ti screen | 福优塞尔® E320 IrO2/Ti foam 福优塞尔® E321 IrO2/Platinized Ti foam 福优塞尔® E322 Pt-IrO2/Platinized Ti foam | 福优塞尔® E330 Ir-carbon paper 福优塞尔® E330T Ir-carbon paper with hydrophobic interface 福优塞尔® E330H Ir-carbon paper with hydrophilic interface | |

福优塞尔® E340T Ir-Ti fiber paper with hydrophobic interface 福优塞尔® E340H Ir-Ti fiber paper with hydrophilic interface 福优塞尔® E341T Ir-Platinized Ti fiber paper with hydrophobic interface 福优塞尔® E341H Ir-Platinized Ti fiber paper with hydrophilic interface | 福优塞尔® E343 Ir/Ti screen 福优塞尔® E344 Ir/Platinized Ti screen 福优塞尔® E345 Pt-Ir/Platinized Ti screen | 福优塞尔® E347 Ir/Ti fiber paper 福优塞尔® E348 Ir/Platinized Ti fiber paper 福优塞尔® E349 Pt-Ir/Platinized Ti fiber paper | 福优塞尔® E351 Ir/Ti foam 福优塞尔® E352 Ir/Platinized Ti foam 福优塞尔® E353 Pt-Ir/Platinized Ti foam | |

Cathode GDE |

DM Raney Ni-Ni fiber paper 福优塞尔® E120 FeCoNi-Ni fiber paper E121 FeCoNi-carbon paper | 福优塞尔® E130 Raney Ni-Ni screen | 福优塞尔® E200 Pt/C-carbon paper 福优塞尔® E210 Pt/C-Ti fiber paper 福优塞尔® E211 Pt/C-Platinized Ti fiber paper 福优塞尔® E214 Pt/C-Ti foam 福优塞尔® E215 Pt/C-Platinized Ti foam | 福优塞尔® E220 Pt black-carbon pape 福优塞尔® E230 Pt black-Ti fiber paper 福优塞尔® E233 Pt black-Platinized Ti fiber paper 福优塞尔® E235 Pt black-Ti foam 福优塞尔® E237 Pt black-Platinized Ti foam |

| Gasket |

PTFE anode gasket (100/200/250/300/400/500/1000μm) (USD$23/each) |

PTFE cathode gasket (100/200/250/300/400/500/1000μm) (USD$23/each) |

FKM anode gasket (100/200/250/300/400/500/1000μm) (USD$23/each) |

FKM cathode gasket (100/200/250/300/400/500/1000μm) (USD$23/each) |

| Tube |

PE tube (ID1/16" OD1/8") (USD$2/m) |

Silicone tube (ID1.6mm/OD4.8mm) (USD$2/m) |

Teflon tube (ID1/16" OD1/8") (USD$10/m) |

tube (ID1.6mm/OD4.8mm) (USD$50/m) |

| Connectors |

ABS bolts (ID1/8"), $10/set |

PTFE bolts (ID1/8"), $15/set |

PTFE bolts (ID1/8"), $20/set |

Nickel bolts (ID1/8"), $20/set |

| Others |  SS nuts, $1/set |

SS spacers, $1/set |

SS springs, $1/set |

Torque wrench with sleeve (1-25 Nm), $100/set |

SS bolts, $1/set |

Spacers, $1/set |

Insulators (T0.5mm), $1/set |

Insulators (T1mm), $1/set | |

Cu conductors, $1/set |

25A High current DC electrical lead pair - Alligator Clip $10/pair/0.5m; $15/pair/1m $20/pair/1.5m; $25/pair/2m |

25A High current DC electrical lead pair -Banana plug to Alligator Clip $10/pair/0.5m; $15/pair/1m $20/pair/1.5m; $25/pair/2m |

35A High current DC electrical lead pair -Banana plug to Alligator Clip $15/pair/0.5m; 20/pair/1m $25/pair/1.5m; $30/pair/2m | |

| Temperature controller, $699 (Accuracy: 0.1°C) | Heating pads ($180/pair) Heating pad binder, $50/25ml | O rings, $2/set |

Wrench kit, $10/set | |

VHP01 vacuum heater | A simple system for electrolyte circulation and gas-liquid separation, $500 | Small peristaltic pump, $300/pc Standard peristaltic pump, $400/pc Standard peristaltic pump with two channels, $700/pc Gear pump, $700/pc | DC power supply with data recording, storage, and export functions, $1000/pc | |

PP isodiametric barbed hose connector Hose IDΦ1-Φ1.6mm, USD$2/pc Hose IDΦ1.6-Φ2.4mm,USD$2/pc Hose IDΦ2.4-Φ3.2mm,USD$2/pc Hose IDΦ3.2-Φ4mm, USD$2/pc Hose IDΦ4-Φ4.8mm, USD$2/pc |

PP barbed connector for variable diameter hoses Hose IDΦ1.6↔Φ2.4, USD$2/pc Hose IDΦ1.6↔Φ3.2,USD$2/pc Hose IDΦ2.4↔Φ3.2, USD$2/pc Hose IDΦ2.4↔Φ4,USD$2/pc Hose IDΦ3.2↔Φ4, USD$2/pc |

PE isodiametric quick connector Tube ODΦ3-Φ3mm, USD$2/pc Tube ODΦ3.2-Φ3.2mm,USD$2/pc Tube ODΦ4-Φ4mm, USD$2/pc |

PE quick connector for variable diameter tubes Tube ODΦ3-Φ3.2mm, USD$2/pc Tube ODΦ3-Φ4mm, USD$2/pc Tube ODΦ3-Φ5mm, USD$2/pc Tube ODΦ3-Φ6mm, USD$2/pc Tube ODΦ3.2-Φ4mm, USD$2/pc Tube ODΦ3.2-Φ6mm, USD$2/pc | |

PTFE corrosion-resistant hose/tube adapter Tube ODΦ3.2mm↔hose IDΦ1.6mm, USD$10/pc Tube ODΦ3.2mm↔hose IDΦ2.4mm, USD$10/pc Tube ODΦ3.2mm↔hose IDΦ3.2mm, USD$10/pc Tube ODΦ3.2mm↔hose IDΦ4mm, USD$10/pc |

PTFE corrosion-resistant isodiametric tube connector Φ3mm↔Φ3mm, USD$10/pc Φ3.2mm↔Φ3.2mm, USD$10/pc Φ4mm↔Φ4mm, USD$10/pc Φ6mm↔Φ6mm, USD$15/pc Φ8mm↔Φ8mm, USD$15/pc |

PTFE corrosion-resistant connector for variable diameter tubes Φ3mm↔Φ3.2mm, USD$15/pc Φ3mm↔Φ4mm, USD$15/pc Φ3mm↔Φ6mm, USD$15/pc Φ3.2mm↔Φ4mm, USD$15/pc Φ4mm↔Φ6mm, USD$15/pc | ||

This alkaline water electrolyzer shows record performance because it contains Sustainion anion exchange membranes

- It operates at high currents: 1 A/cm2 at about 1.9 V at 60 °C in flowing 1 M KOH.

- There is no need for precious metals.

- The electrolyzer can be rapidly turned on and turned off.

- The electrolyzer design allows one to replace PEM electrolyzers with alkaline water electrolyzers and get similar performance.

INSTRUCTIONS FOR USE

Initial set up for DM Alkaline Water Electrolyzer Cell

-System set up (recommended)

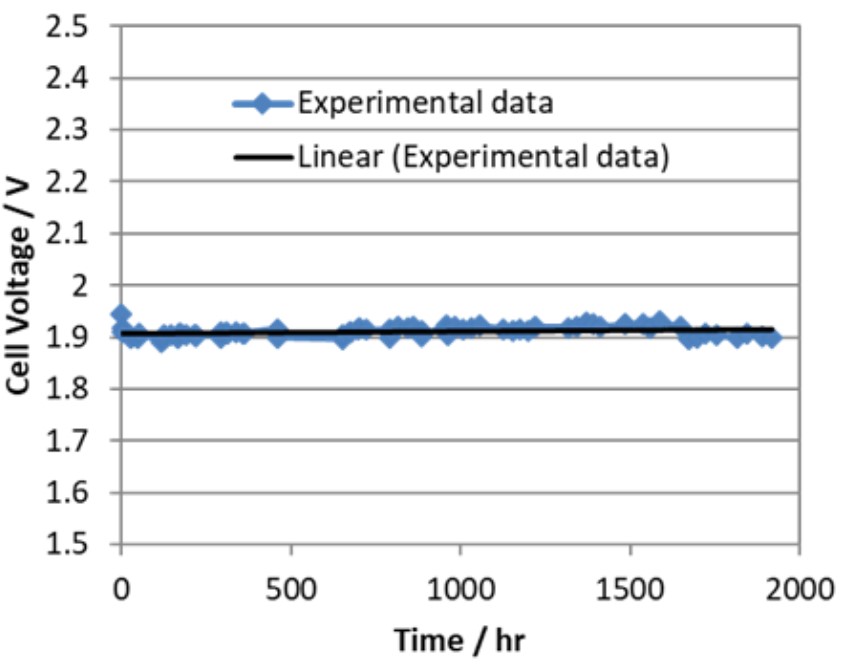

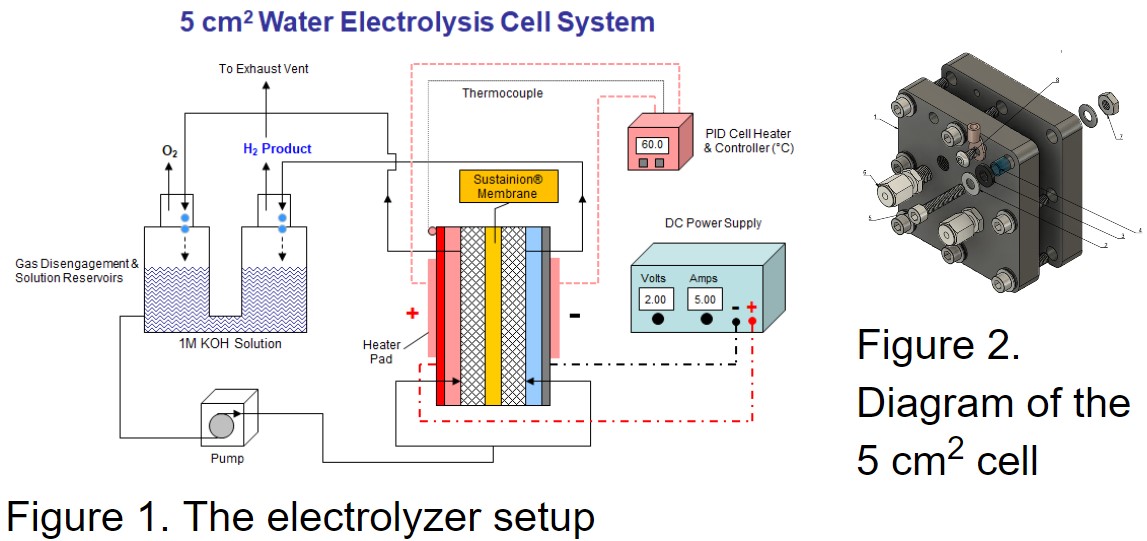

Typically, the system setup uses a peristaltic pump to meter a 1M KOH solution that is split evenly to both the anode and cathode from a common solution reservoir with two separate gas disengagements (Figure 1). The total pump flowrate is about 3 mL/min. The suggested tubing used is a 1/8” OD, 1/16” ID PTFE tubing. The length of tubing after the split into the two flow streams into the two electrode compartments should be at least 8 inches (20 cm) on each side in order to reduce the amount of current leakage (or shunt current) between the anode and cathode. The exit liquid streams with gases from the two electrode compartments are separately routed to the gas disengager which allows the liquid to drop into the separate sections, so the two product gases are not mixed together. Meanwhile gas disengager also acts as a current break.

-Fluid Connections

The fluid inlet and outlet ports are located in the center of the cell (Figure 2). Connect the PTFE tubing (1/8” OD) from the pump to the compression fitting (#6) located at the bottom; connect another PTFE tubing (1/8” OD) from the gas disengage to the compression fitting (#6) the top; and tighten the nut with finger. Repeat this for the other side of the cell.

-Power Connections

Locate the threaded hole for wire connection on top of the cell (smaller through-hole 8-32 thread). Then connect the ring terminal with the Phillips round head screw (#9). Use this same procedure for both anode and cathode.

Cell Testing and Operation

Begin pumping a 1M KOH solution from bottom connection of the solution reservoir and gas disengager at a rate of 3 mL/min which is split into two flow streams, one going to inlet of the anode chamber and the other to the cathode chamber. Then begin heating the cell by turning on the temperature controller and setting the temperature to 60°C (heaters sold separately) and holding the temperature at 60°C for at least 30 min before applying current. Connect the anode electrical lead (red) and cathode lead (black) to the positive and negative connections, respectively, on the power supply with electric wires/cables (not included). Set the power supply voltage at 2.2V and slowly begin increasing the current to a setting of 5 A (1A/cm2). The cell current will reach the desired 5A in a few min or hours depending on the cell membrane and electrode conditioning. Testing can also be done with potentiostat, but the connections depend on the testing protocol.

For international orders, please ask us for quotes via

Email: contact@scimaterials.cn

Tel: +86 15375698751

Wechat: SCI-Materials-Hub

Clik here to put quick orders on our Alibaba shop

DM Complete 5 cm2 AEM Water Electrolyzer | |

Product Code | 130101 |

| Description | DM Complete 5 cm2 AEM Water Electrolyzer |

| Price (US$) | Ask for quote |

Lead Time & Availability | 2-3 weeks |

SCI Materials Hub Is Committed to Offering The Best Price & Customer Services! | |

Worldwide shipping via DHL, SF-Express & other requested carriers.

Payments via Bank Transfer, Paypal, Credit card (via Taobao), Alipay, Wechat-pay are accepted.

Partial references citing our materials (from Google Scholar)

Carbon Dioxide Reduction

1. ACS Nano Strain Relaxation in Metal Alloy Catalysts Steers the Product Selectivity of Electrocatalytic CO2 Reduction

The bipolar membrane (Fumasep FBM) in this paper was purchased from SCI Materials Hub, which was used in rechargeable Zn-CO2 battery tests. The authors reported a strain relaxation strategy to determine lattice strains in bimetal MNi alloys (M = Pd, Ag, and Au) and realized an outstanding CO2-to-CO Faradaic efficiency of 96.6% with outstanding activity and durability toward a Zn-CO2 battery.

2. Front. Chem. Boosting Electrochemical Carbon Dioxide Reduction on Atomically Dispersed Nickel Catalyst

In this paper, Vulcan XC-72R was purchased from SCI Materials Hub. Vulcan XC 72R carbon is the most common catalyst support used in the anode and cathode electrodes of Polymer Electrolyte Membrane Fuel Cells (PEMFC), Direct Methanol Fuel Cells (DMFC), Alkaline Fuel Cells (AFC), Microbial Fuel Cells (MFC), Phosphoric Acid Fuel Cells (PAFC), and many more!

3. Adv. Mater. Partially Nitrided Ni Nanoclusters Achieve Energy-Efficient Electrocatalytic CO2 Reduction to CO at Ultralow Overpotential

An AEM membrane (Sustainion X37-50 Grade RT, purchased from SCI Materials Hub) was activated in 1 M KOH for 24 h, washed with ultra-purity water prior to use.

4. Adv. Funct. Mater. Nanoconfined Molecular Catalysts in Integrated Gas Diffusion Electrodes for High-Current-Density CO2 Electroreduction

In this paper (Supporting Information), an anion exchanged membrane (Fumasep FAB-PK-130 obtained from SCI Materials Hub (www.scimaterials.cn)) was used to separate the catholyte and anolyte chambers.

SCI Materials Hub: we also recommend our Fumasep FAB-PK-75 for the use in a flow cell.

5. Appl. Catal. B Efficient utilization of nickel single atoms for CO2 electroreduction by constructing 3D interconnected nitrogen-doped carbon tube network

In this paper, the Nafion 117 membrane was obtained from SCI Materials Hub.

In this paper, Proton exchange membrane (Nafion 117), Nafion D520, and Toray 060 carbon paper were purchased from SCI Materials Hub.

7. National Science Review Confinement of ionomer for electrocatalytic CO2 reduction reaction via efficient mass transfer pathways

An anion exchange membrane (PiperION-A15-HCO3) was obtained from SCI Materials Hub.

8. Catalysis Communications Facilitating CO2 electroreduction to C2H4 through facile regulating {100} & {111} grain boundary of Cu2O

Carbon paper (TGPH060), membrane solution (Nafion D520), and ionic membrane (Nafion N117) were obtained from Wuhu Eryi Material Technology Co., Ltd (a company under SCI Materials Hub).

Batteries

1. J. Mater. Chem. A Blocking polysulfides with a Janus Fe3C/N-CNF@RGO electrode via physiochemical confinement and catalytic conversion for high-performance lithium–sulfur batteries

Graphene oxide (GO) in this paper was obtained from SCI Materials Hub. The authors introduced a Janus Fe3C/N-CNF@RGO electrode consisting of 1D Fe3C decorated N-doped carbon nanofibers (Fe3C/N-CNFs) side and 2D reduced graphene oxide (RGO) side as the free-standing carrier of Li2S6 catholyte to improve the overall electrochemical performance of Li-S batteries.

This paper used more than 10 kinds of materials from SCI Materials Hub and the authors gave detailed properity comparsion.

The commercial IEMs of Fumasep FAB-PK-130 and Nafion N117 were obtained from SCI Materials Hub.

Gas diffusion layers of GDL340 (CeTech) and SGL39BC (Sigracet) and Nafion dispersion (Nafion D520) were obtained from SCI Materials Hub.

Zn foil (100 mm thickness) and Zn powder were obtained from the SCI Materials Hub.

Commercial 20% Pt/C, 40% Pt/C and IrO2 catalysts were also obtained from SCI Materials Hub.

3. Journal of Energy Chemistry Vanadium oxide nanospheres encapsulated in N-doped carbon nanofibers with morphology and defect dual-engineering toward advanced aqueous zinc-ion batteries

In this paper, carbon cloth (W0S1011) was obtained from SCI Materials Hub. The flexible carbon cloth matrix guaranteed the stabilization of the electrode and improved the conductivity of the cathode.

4. Energy Storage Materials Defect-abundant commercializable 3D carbon papers for fabricating composite Li anode with high loading and long life

The 3D carbon paper (TGPH060 raw paper) were purchased from SCI Materials Hub.

5. Nanomaterials A Stable Rechargeable Aqueous Zn–Air Battery Enabled by Heterogeneous MoS2 Cathode Catalysts

Nafion D520 (5 wt%), and carbon paper (GDL340) were received from SCI-Materials-Hub.

Carbon cloth (W0S1011) and other electrochemical consumables required for air cathode were provided by SCI Materials Hub.

Oxygen Reduction Reaction

1. J. Chem. Eng. Superior Efficiency Hydrogen Peroxide Production in Acidic Media through Epoxy Group Adjacent to Co-O/C Active Centers on Carbon Black

In this paper, Vulcan XC 72 carbon black, ion membrane (Nafion N115, 127 μL), Nafion solution (D520, 5 wt%), and carbon paper (AvCarb GDS 2230 and Spectracarb 2050A-1050) were purchased from SCI Materials Hub.

2. Journal of Colloid and Interface Science Gaining insight into the impact of electronic property and interface electrostatic field on ORR kinetics in alloy engineering via theoretical prognostication and experimental validation

The 20 wt% Pt3M (M = Cr, Co, Cu, Pd, Sn, and Ir) were purchased from SCI Materials Hub. This work places emphasis on the kinetics of the ORR concerning Pt3M (M = Cr, Co, Cu, Pd, Sn, and Ir) catalysts, and integrates theoretical prognostication and experimental validation to illuminate the fundamental principles of alloy engineering.

Water Electrolysis

1. International Journal of Hydrogen Energy Gold as an efficient hydrogen isotope separation catalyst in proton exchange membrane water electrolysis

The cathodic catalysts of Pt/C (20 wt%, 2–3 nm) and Au/C (20 wt%, 4–5 nm) were purchased from SCI Materials Hub.

2. Small Science Silver Compositing Boosts Water Electrolysis Activity and Durability of RuO2 in a Proton-Exchange-Membrane Water Electrolyzer

Two fiber felts (0.35 mm thickness, SCI Materials Hub) were used as the porous transport layers at both the cathode and the anode.

3. Advanced Functional Materials Hierarchical Crystalline/Amorphous Heterostructure MoNi/NiMoOx for Electrochemical Hydrogen Evolution with Industry-Level Activity and Stability

Anion-exchange membrane (FAA-3-PK-130) was obtained from SCI Materials Hub website.

Fuel Cells

1. Polymer Sub-two-micron ultrathin proton exchange membrane with reinforced mechanical strength

Gas diffusion electrode (60% Pt/C, Carbon paper) was purchased from SCI Materials Hub.

Characterization

1. Chemical Engineering Journal Electrochemical reconstitution of Prussian blue analogue for coupling furfural electro-oxidation with photo-assisted hydrogen evolution reaction

An Au nanoparticle film was deposited on the total reflecting plane of a single reflection ATR crystal (SCI Materials Hub, Wuhu, China) via sputter coater.

|

We Provide A Broad Range of Materials, Instruments & Solutions in Advanced Science and Technologies | About Us |