The Fueiceel® PSC Series PEM Electrolyzers represent an advanced generation of patented pure-water hydrogen generators.

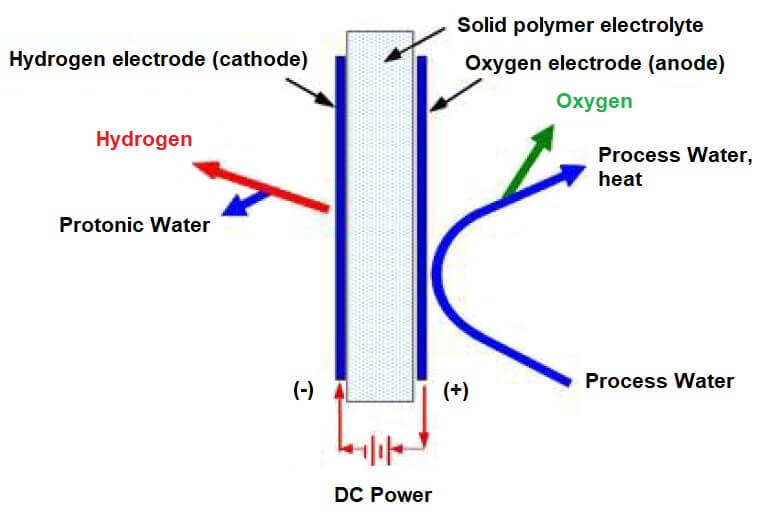

These systems employ proton exchange membrane (PEM) or solid polymer electrolyte (SPE) technology, delivering high efficiency, low voltage operation, and zero chemical additives—enabling stable production of high-purity hydrogen and oxygen.

The electrolyzer stack utilizes high-strength titanium components and high-activity catalyst-coated membranes (CCM).

With nearly zero electrode spacing and minimal internal resistance, PSC electrolyzers achieve superior efficiency, durability, and corrosion resistance compared to conventional alkaline systems.

The proton exchange membrane selectively conducts protons (H⁺) while blocking electrons and gases. This allows pure-water electrolysis without alkaline electrolytes, eliminating safety and corrosion concerns.

Under a DC voltage:

At the anode (oxidation): 2H₂O → 4H⁺ + 4e⁻ + O₂

At the cathode (reduction): 4H⁺ + 4e⁻ → 2H₂

Only hydrogen, oxygen, and a trace amount of water vapor are produced — making the process clean, safe, and environmentally friendly.

(Figure 1. Schematic of PEM Electrolyzer Stack)

✅ Renewable energy hydrogen production and energy storage

✅ Laboratory and research hydrogen generation

✅ Analytical gas supply systems

✅ Hydrogen therapy and cosmetic devices

✅ Special fuel and chemical synthesis

✅ Hydrogen supply for fuel cells

✅ Other high-purity hydrogen applications

| Feature | Description |

|---|---|

| Pure-water operation | Requires only deionized or distilled water; no alkaline additives needed |

| High-purity hydrogen | Ultra-clean gas output with minimal contaminants |

| Corrosion-resistant structure | Titanium and inert components ensure long-term stability |

| High efficiency | Minimal internal resistance and low energy consumption |

| Easy maintenance | No corrosion, no pollution, long desiccant lifetime |

| Safe and eco-friendly | No caustic electrolyte, no harmful gas emissions |

Custom-designed electrolyzer stacks and specifications are available upon request.

| Product Code | Model | Stack Layers | Stack Diameter (mm) | H₂ Flow (mL/min) | Voltage (V DC) | Max Current (A DC) | Water Use (cc/h) |

|---|---|---|---|---|---|---|---|

| 2710060 | PSC60 | 1 | 85 | 0–60 | 2 | 9 | 4 |

| 2710120 | PSC120 | 2 | 85 | 0–120 | 4 | 9 | 8 |

| 2710180 | PSC180 | 3 | 85 | 0–180 | 6 | 9 | 12 |

| 2710240 | PSC240 | 4 | 85 | 0–240 | 8 | 9 | 16 |

| 2710300 | PSC300 | 1 | 138 | 0–300 | 2 | 40 | 18 |

| 2710500 | PSC500 | 2 | 138 | 0–500 | 4 | 40 | 30 |

| 2710750 | PSC750 | 3 | 138 | 0–750 | 6 | 40 | 45 |

| 2711000 | PSC1000 | 4 | 138 | 0–1000 | 8 | 40 | 60 |

| 2712000 | PSC2000 | 8 | 138 | 0–2000 | 16 | 40 | 60 |

Operating temperature: 5 – 45°C

Output pressure: 0 – 10 barg (0 – 145 psi)

Membrane type: Nafion® PFSA

Diffusion layer: Sintered titanium

Electrode: Noble-metal catalyst

Feedwater: Deionized or distilled water (>1 MΩ·cm, conductivity<1 μS/cm)

Expected lifetime: ~10,000 hours (under ideal water and power conditions)

Clamp Material: Aluminum alloy for small models; stainless steel for larger ones

Bipolar Plate: TA1-grade titanium

Water Tubing: Silicone hose (ID 6 mm, OD 9–10 mm)

Max Electrode Area: Up to 0.5 m² (customizable)

(Figure 2. PSC Series PEM Electrolyzer – Structural Layout)

For inquiries, specifications, or purchasing, please contact our authorized sales channels.

Fueiceel® and ChemXpert™ are committed to providing high-performance materials and professional technical support.

Q1: What materials are used for the clamps and bipolar plates?

Clamps — Aluminum alloy (small models) / Stainless steel (large models)

Bipolar plates — High-purity titanium (TA1), ensuring corrosion resistance and excellent conductivity.

Q2: What is the maximum electrode area?

Up to 0.5 m².

Typical effective areas by model:

Q3: What type of water tubing does the PSC120 model use?

PSC120 uses silicone tubing: ID 6 mm / OD 9–10 mm, offering excellent temperature and pressure resistance.

Q4: What is the expected service life?

Under stable power and high-purity water conditions, the PSC series can operate up to 10,000 hours.

Q5: Do I need to add alkali to the water?

No. The PSC series uses pure-water electrolysis—only deionized or distilled water is required. Do not add alkaline electrolytes.

Q6: What are the power requirements for PSC2000?

Input voltage: 24V ±20%, current: 36A, typical working voltage: 17–20V.

📧 Email: contact@scimaterials.cn

📞 WhatsApp & Tel: +86 153-7569-8751

🔗 Place quick orders on our eBay / Amazon / Alibaba stores.

🌐 We ship worldwide via DHL, FedEx, UPS, SF-Express, or other requested carriers.

📦 Bulk quantities with discount available upon request.

💳 Payment methods accepted: Bank Wire Transfer, PayPal, Credit Card (via Taobao), Alipay, WeChat Pay

⚙️ Fueiceel® PSC Series Proton Exchange Membrane (PEM) Electrolyzers · Specifications & Price List (USD$)

| Product Code | Model | Stack Layers | H₂ Flow (mL/min) | Voltage (V DC) | Max Current (A DC) | Water Use (cc/h) | Diameter (mm) | Price (USD) | Lead Time |

|---|---|---|---|---|---|---|---|---|---|

| 2710060 | PSC60 | 1 | 0 – 60 | 2 | 9 | 4 | Ø85 | $596 | 3–5 days |

| 2710120 | PSC120 | 2 | 0 – 120 | 4 | 9 | 8 | Ø85 | $796 | 3–5 days |

| 2710180 | PSC180 | 3 | 0 – 180 | 6 | 9 | 12 | Ø85 | $996 | 3–5 days |

| 2710240 | PSC240 | 4 | 0 – 240 | 8 | 9 | 16 | Ø85 | $1,196 | 3–5 days |

| 2710300 | PSC300 | 1 | 0 – 300 | 2 | 40 | 18 | Ø138 | $1,396 | 3–5 days |

| 2710500 | PSC500 | 2 | 0 – 500 | 4 | 40 | 30 | Ø138 | $1,796 | 3–5 days |

| 2710750 | PSC750 | 3 | 0 – 750 | 6 | 40 | 45 | Ø138 | $2,196 | 3–5 days |

| 2711000 | PSC1000 | 4 | 0 – 1000 | 8 | 40 | 60 | Ø138 | $2,596 | 3–5 days |

| 2712000 | PSC2000 | 8 | 0 – 2000 | 16 | 40 | 60 | Ø138 | $4,996 | 3–5 days |

Operating temperature: 5 °C – 45 °C

Output pressure: 0 – 10 barg (0 – 145 psi)

Membrane: Nafion® PFSA

Diffusion layer: Sintered titanium

Electrode: Noble metal catalyst

Feed water: Deionized / distilled water (conductivity < 1 μS/cm)

Expected lifetime: ≥ 10,000 hours

Partial references citing our materials (from Google Scholar)

Carbon Dioxide Reduction

1. ACS Nano Strain Relaxation in Metal Alloy Catalysts Steers the Product Selectivity of Electrocatalytic CO2 Reduction

The bipolar membrane (Fumasep FBM) in this paper was purchased from SCI Materials Hub, which was used in rechargeable Zn-CO2 battery tests. The authors reported a strain relaxation strategy to determine lattice strains in bimetal MNi alloys (M = Pd, Ag, and Au) and realized an outstanding CO2-to-CO Faradaic efficiency of 96.6% with outstanding activity and durability toward a Zn-CO2 battery.

2. Front. Chem. Boosting Electrochemical Carbon Dioxide Reduction on Atomically Dispersed Nickel Catalyst

In this paper, Vulcan XC-72R was purchased from SCI Materials Hub. Vulcan XC 72R carbon is the most common catalyst support used in the anode and cathode electrodes of Polymer Electrolyte Membrane Fuel Cells (PEMFC), Direct Methanol Fuel Cells (DMFC), Alkaline Fuel Cells (AFC), Microbial Fuel Cells (MFC), Phosphoric Acid Fuel Cells (PAFC), and many more!

3. Adv. Mater. Partially Nitrided Ni Nanoclusters Achieve Energy-Efficient Electrocatalytic CO2 Reduction to CO at Ultralow Overpotential

An AEM membrane (Sustainion X37-50 Grade RT, purchased from SCI Materials Hub) was activated in 1 M KOH for 24 h, washed with ultra-purity water prior to use.

4. Adv. Funct. Mater. Nanoconfined Molecular Catalysts in Integrated Gas Diffusion Electrodes for High-Current-Density CO2 Electroreduction

In this paper (Supporting Information), an anion exchanged membrane (Fumasep FAB-PK-130 obtained from SCI Materials Hub (www.scimaterials.cn)) was used to separate the catholyte and anolyte chambers.

SCI Materials Hub: we also recommend our Fumasep FAB-PK-75 for the use in a flow cell.

5. Appl. Catal. B Efficient utilization of nickel single atoms for CO2 electroreduction by constructing 3D interconnected nitrogen-doped carbon tube network

In this paper, the Nafion 117 membrane was obtained from SCI Materials Hub.

In this paper, Proton exchange membrane (Nafion 117), Nafion D520, and Toray 060 carbon paper were purchased from SCI Materials Hub.

7. National Science Review Confinement of ionomer for electrocatalytic CO2 reduction reaction via efficient mass transfer pathways

An anion exchange membrane (PiperION-A15-HCO3) was obtained from SCI Materials Hub.

8. Catalysis Communications Facilitating CO2 electroreduction to C2H4 through facile regulating {100} & {111} grain boundary of Cu2O

Carbon paper (TGPH060), membrane solution (Nafion D520), and ionic membrane (Nafion N117) were obtained from Wuhu Eryi Material Technology Co., Ltd (a company under SCI Materials Hub).

Batteries

1. J. Mater. Chem. A Blocking polysulfides with a Janus Fe3C/N-CNF@RGO electrode via physiochemical confinement and catalytic conversion for high-performance lithium–sulfur batteries

Graphene oxide (GO) in this paper was obtained from SCI Materials Hub. The authors introduced a Janus Fe3C/N-CNF@RGO electrode consisting of 1D Fe3C decorated N-doped carbon nanofibers (Fe3C/N-CNFs) side and 2D reduced graphene oxide (RGO) side as the free-standing carrier of Li2S6 catholyte to improve the overall electrochemical performance of Li-S batteries.

This paper used more than 10 kinds of materials from SCI Materials Hub and the authors gave detailed properity comparsion.

The commercial IEMs of Fumasep FAB-PK-130 and Nafion N117 were obtained from SCI Materials Hub.

Gas diffusion layers of GDL340 (CeTech) and SGL39BC (Sigracet) and Nafion dispersion (Nafion D520) were obtained from SCI Materials Hub.

Zn foil (100 mm thickness) and Zn powder were obtained from the SCI Materials Hub.

Commercial 20% Pt/C, 40% Pt/C and IrO2 catalysts were also obtained from SCI Materials Hub.

3. Journal of Energy Chemistry Vanadium oxide nanospheres encapsulated in N-doped carbon nanofibers with morphology and defect dual-engineering toward advanced aqueous zinc-ion batteries

In this paper, carbon cloth (W0S1011) was obtained from SCI Materials Hub. The flexible carbon cloth matrix guaranteed the stabilization of the electrode and improved the conductivity of the cathode.

4. Energy Storage Materials Defect-abundant commercializable 3D carbon papers for fabricating composite Li anode with high loading and long life

The 3D carbon paper (TGPH060 raw paper) were purchased from SCI Materials Hub.

5. Nanomaterials A Stable Rechargeable Aqueous Zn–Air Battery Enabled by Heterogeneous MoS2 Cathode Catalysts

Nafion D520 (5 wt%), and carbon paper (GDL340) were received from SCI-Materials-Hub.

Carbon cloth (W0S1011) and other electrochemical consumables required for air cathode were provided by SCI Materials Hub.

Oxygen Reduction Reaction

1. J. Chem. Eng. Superior Efficiency Hydrogen Peroxide Production in Acidic Media through Epoxy Group Adjacent to Co-O/C Active Centers on Carbon Black

In this paper, Vulcan XC 72 carbon black, ion membrane (Nafion N115, 127 μL), Nafion solution (D520, 5 wt%), and carbon paper (AvCarb GDS 2230 and Spectracarb 2050A-1050) were purchased from SCI Materials Hub.

2. Journal of Colloid and Interface Science Gaining insight into the impact of electronic property and interface electrostatic field on ORR kinetics in alloy engineering via theoretical prognostication and experimental validation

The 20 wt% Pt3M (M = Cr, Co, Cu, Pd, Sn, and Ir) were purchased from SCI Materials Hub. This work places emphasis on the kinetics of the ORR concerning Pt3M (M = Cr, Co, Cu, Pd, Sn, and Ir) catalysts, and integrates theoretical prognostication and experimental validation to illuminate the fundamental principles of alloy engineering.

Water Electrolysis

1. International Journal of Hydrogen Energy Gold as an efficient hydrogen isotope separation catalyst in proton exchange membrane water electrolysis

The cathodic catalysts of Pt/C (20 wt%, 2–3 nm) and Au/C (20 wt%, 4–5 nm) were purchased from SCI Materials Hub.

2. Small Science Silver Compositing Boosts Water Electrolysis Activity and Durability of RuO2 in a Proton-Exchange-Membrane Water Electrolyzer

Two fiber felts (0.35 mm thickness, SCI Materials Hub) were used as the porous transport layers at both the cathode and the anode.

3. Advanced Functional Materials Hierarchical Crystalline/Amorphous Heterostructure MoNi/NiMoOx for Electrochemical Hydrogen Evolution with Industry-Level Activity and Stability

Anion-exchange membrane (FAA-3-PK-130) was obtained from SCI Materials Hub website.

Fuel Cells

1. Polymer Sub-two-micron ultrathin proton exchange membrane with reinforced mechanical strength

Gas diffusion electrode (60% Pt/C, Carbon paper) was purchased from SCI Materials Hub.

Characterization

1. Chemical Engineering Journal Electrochemical reconstitution of Prussian blue analogue for coupling furfural electro-oxidation with photo-assisted hydrogen evolution reaction

An Au nanoparticle film was deposited on the total reflecting plane of a single reflection ATR crystal (SCI Materials Hub, Wuhu, China) via sputter coater.

|

We Provide A Broad Range of Materials, Instruments & Solutions in Advanced Science and Technologies | About Us |