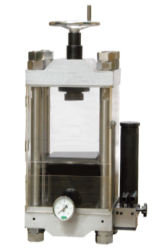

1. YLJ01 Small Manual Hydraulic Press

| 1.1 Parameters Table | |||||

Model | YLJ01-10T (2 Columns) | YLJ01-15T (2 Columns) | YLJ01-15T (4 Columns) | YLJ01-24T (4 Columns) | YLJ01-30T (4 Columns) |

| Pressure Range | 0~10 tons | 0~15 tons | 0~15 tons | 0~24 tons | 0~30 tons |

| Pressure Range | 0~16.7MPa | 0~25MPa | 0~25MPa | 0~40MPa | 0~35MPa |

| Piston Diameter | 87mm | 87mm | 87mm | 87mm | 105mm |

| Maximum Piston Stroke | 20mm | 20mm | 20mm | 20mm | 20mm |

| Workspace | 140×140×120mm | 140×140×150mm | 94×94×150mm | 94×94×140mm | 140×140×150mm |

| Pressure Stability | ≤1Mpa/5min | ≤1Mpa/5min | ≤1Mpa/5min | ≤1Mpa/5min | ≤1Mpa/5min |

| Weight | 35kg | 35kg | 36kg | 40kg | 50kg |

| Exterior Size | 280×210×500mm | 280×210×500mm | 280×210×500mm | 280×260×500mm | 325×230×550mm |

Product Image |  |  |

|  |  |

| 1.2 Pressure Conversion Table | ||||||||

YLJ01-10T (2 Columns) | Cylinder Pressure (T) | 3 | 6 | 9 | 10 | / | / | / |

Indication on the pressure gauge (Mpa) | 5 | 10 | 15 | 16.5 | / | / | / | |

YLJ01-15T (4 Columns) | Cylinder Pressure (T) | 3 | 6 | 9 | 12 | 15 | / | / |

Indication on the pressure gauge (Mpa) | 5 | 10 | 15 | 20 | 25 | / | / | |

YLJ01-24T (4 Columns) | Cylinder Pressure (T) | 3 | 6 | 9 | 12 | 15 | 20 | 24 |

Indication on the pressure gauge (Mpa) | 5 | 10 | 15 | 20 | 25 | 33.4 | 40 | |

YLJ01-30T (4 Columns) | Cylinder Pressure (T) | 4.3 | 8.6 | 12.9 | 17.2 | 21.5 | 25.8 | 30 |

| Indication on the pressure gauge (Mpa) | 5 | 10 | 15 | 20 | 25 | 30 | 35 | |

| 1.3 Instrument structure (Illustration 1.1) | |||

| No. | Name | No. | Name |

| 1 | Hand wheel | 9 | Worktable |

| 2 | Screw | 10 | Pressure gauge |

| 3 | Nut | 11 | Manual handle |

| 4 | Columm | 12 | Piston pump |

| 5 | Metal plate | 13 | Oil-injecting screw |

| 6 | Big oil cylinder | 14 | Position-setting screw |

| 7 | Big board | 15 | Oil-suction valve |

| 8 | Oil pool | 16 | Delivery valve |

YLJ01-10T (2 Columns) |

YLJ01-15T (4 Columns) |

YLJ01-24T (4 Columns) |

YLJ01-30T (4 Columns) |

[Procedure (See illustration 1.1)]

Loosen the oil-injecting screw (13), then tighten the oil-draining valve (7) clockwise. Place the mould on the center ofthe worktable (9). After tightening the screw (2), swing themanual handle (11) forward and backward to achieve the re-quired pressure. After dwelling, loosen the oil-draining valve (7) anticlockwise and remove the mould.

[The scope of application]

The instrument is mainly used in infrared spectrophotometer sample preparation of solid samples and a variety of small powder tablet molding. Widely used in catalysis, silicates, batteries, ceramics and powder metallurgy and other industries.

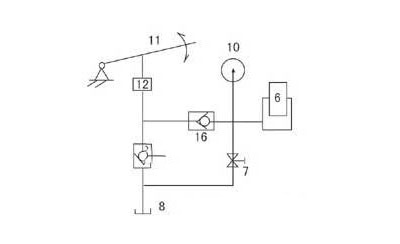

[Principle of Oil Channel (See Illustration 1.2)]

The oil-draining valve (7) is closed during the working process. When swinging the manual handle (11), the oil is suck from oiI poll (8) through the one-way valve (15) then it enters the big oil cylinder (6) through the one-way delivery valve (16). Thus great energy is accumulated,which produces high- pressure oil and the indication can beread on the pressure gauge (10). When opening the oil-draining valve (7), the energy unloads.

Illustration 1.2 YLJ01 Small Manual Hydraulic Press Principle of Oil Channel

[Notice]

1. LOOSEN the oil- ijecting screw (13) before operating the press.

2. Add the lubricating oil in the screw (2) and piston pump (12) regularly.

3. To avoid accident, pressurization MUST be within thepressure -range of the press.

4. It is recommended to use the clean machine oil (No. 46). Breakoil is strictly FORBIDDEN to be used in the press.

5. During pressurization, if force can be felt on the manual handle (11) with no indication on pressure gauge (10) , please unload IMMEDI-ATELY and check the pressure gauge (10) .

6. For the new or long-unused press, it is necessary to tighten theoil- draining valve (7) a little before operating the press. Then pressurizeto 20-25MPa and unload. Repeat this process twice or three timesthen the press can work properly.

7. Piston stroke MUST be within 20mm.

| 1.4 Troubleshooting | ||

| Malfunction | Reasons | Solution |

| No Pressure | 1. The steel-ball in deliveryvalve (16) has not been tightlysealed, or there is foreignbody in delivery valve (16). 2. There is no oil in the oil pool (8). | 1. Loosen the screw in the delivery valve (16) with a 6mm hexagon wrench indiameter and take out the spring. Use a6mm pontil in diameter with its one endsticking to the steel-ball and another end (A magnet should be attached there inadvance. absorbing the steel-ball. Get ridof the scrap iron or foreign body thenassemble the parts orderly. 2. Loosen the screw in the delivery valve (15). After injecting oil,press the valveby fingers and swing the manual handle (11). When force can be felt from oiluntil uncontrollable, tighten the screw. 3. Add the NO.30 clean machine oilthrough the oil-injecting hole. |

Unstable And Slow Pressurization | 1. The oil leaks from the screw. 2. There is insufficient tighten-ing force in the oil-drainingvalve (7). 3. There is residual gas in thelittle piston pump (12). 4. There is residual gas in thebig oil cylinder (6). | 1. Find out and eliminate the oil-leakingspot. 2. Tighten the handwheel of the oil-draining valve (7). 3. Overturn the whole set of the machine90 o backward and swing the manualhandle (11) several times. (Oil-injectingscrew (13) needs to be tightened beforeoverturning the machine.) 4. Loosen the bolt (on the top of the piston(6))and tighten the handwheel of theoil-draining valve (7). Pressurize untilthe overflow of oil and tighten the screw. |

| Bend of Screw | 1. Pressurization over 25MPa for YLJ01-15T, or pressurization over 40MPa for YLJ01-24T. 2. Loosening of the big nut ofthe column. | 1. Straighten the screw or change a new one. 2. Tighten the big nut. |

2. YLJ01 Medium Manual Hydraulic Press

| 2.1 Parameters Table | ||

| Model | YLJ01-40T (4 Columns) | YLJ01-60T (4 Columns) |

| Pressure Range | 0~40 tons | 0~60 tons |

| Pressure Range | 0~33.3Mpa | 0~34Mpa |

| Piston Diameter | 125mm | 150mm |

| Maximum Piston Stroke | 40mm | 40mm |

| Workspace | 180×180×210mm | 220×220×260mm |

| Pressure Stability | ≤1Mpa/5min | ≤1Mpa/5min |

| Weight | 100kg | 155kg |

| Exterior Size | 350×260×620mm | 445×240×740mm |

| Product Image |  |  |

| 2.2 Pressure Conversion Table | ||||||||

YLJ01-40T (4 Columns) | Cylinder Pressure (T) | 6 | 12 | 18 | 24 | 30 | 36 | 40 |

Indication on the pressure gauge (Mpa) | 5 | 10 | 15 | 20 | 25 | 30 | 33.3 | |

YLJ01-60T (4 Columns) | Cylinder Pressure (T) | 8.8 | 17.6 | 26.4 | 35.2 | 44 | 52.8 | 60 |

Indication on the pressure gauge (Mpa) | 5 | 10 | 15 | 20 | 25 | 30 | 34 | |

| 2.3 Instrument structure (Illustration 2.1) | |||

| NO. | Name | NO. | Name |

| 1 | Oil cylinder | 11 | Main board |

| 2 | Pressure gauge | 12 | Piston |

| 3 | Low pressure valve | 13 | Table guide |

| 4 | Small piston | 14 | Worktable |

5 | High pressure valve | 15 | Shield |

| 6 | Oil-drainng valve | 16 | Column |

| 7 | High pressure valve | 17 | Screw |

| 8 | Low pressure relief valve | 18 | Upper |

| 9 | Vice board | 19 | Nut |

| 10 | Low pressure valve | 20 | Hand wheel |

YLJ01-40T (4 Columns) |

YLJ01-60T (4 Columns) | ||

[Procedure (See illustration 2.1)]

Loosen screw oil tube 1, tighten the oil drain valve 6, open the door for 15, 14, pull out the workbench will die (or pressure) on the workbench 14, then 14 advance to the workbench, the compression with screw 17 items preloaded, shut the door 15, shake small piston 4 pressure, to the compression pressure, pressure to the required pressure, loose open valve 6, Remove the pressurized items.

[The scope of application]

The instrument is mainly used in the preparation of solid samples and various small powder tablet forming on the fluorescence spectrometer. Widely used in catalysis, silicate, battery, ceramics, powder metallurgy and other industries.

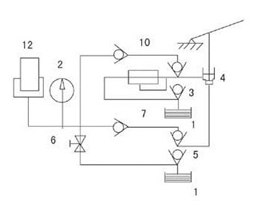

[Principle of Oil Channel (See Illustration 2.2)]

The oil in cylinder 1 goes through small piston 4, and then through low pressure valve 3 and 10, high pressure valve 5 and 7 into big piston 12. The pressure is displayed by pressure gauge 2, and the oil in big piston 12 returns to cylinder 1 under the action of pressure, and the big piston 12 is reset.

Illustration 2.2: YLJ01 Medium Manual Hydraulic Press Principle of Oil Channel

[Notice]

1. Before use, loosen the screw on oil cylinder 1 (tighten the screw during transportation), loosen the oil valve 6, shake the pressure handle of small piston 4, and empty the air several times to remove the air in the system.

2. the force should not be too large when using the lead screw 17 to pretighten the compression items.

3.The stroke of large piston cannot exceed 50mm.

4. During maintenance, close the valve of the back seat of the oil cylinder to avoid the oil flow out of the oil cylinder 1.

5. Pressure is not allowed to exceed the pressure range, in order to avoid danger.

6. The oil in barrel 1 is 46# oil.

| 2.4 Troubleshooting | ||

| Malfunction | Reasons | Solution |

| No Pressure | 1. The oil leaks from the screw. 2. The drain valve is not tightend. | 1. Replace the gasket and solve the leak. 2. screw down. 3. Press the large piston to the bottom. |

Off the pressure | 1. The oil leaks from the screw. 2. The outlet valve is not strict or there are foreign bodies. 3. There is residual gas in piston3. | 1. Find out the small oil leakage and eliminate it 2. Close the maintenance screw, and unscrew the oil discharge valve stem. Connect the iron rod with a magnet to suck out the steel ball. 3. Unscrew the top of the piston, tighten the handwheel of the oil release valve, and press until the liquid oil overflows. |

| Machine deformation | 1. The pressure is high and the column nut is loose due to. 2. Exceed allowable pressure. | 1. Tighten the column or the column nut. 2. Reduce the use pressure, otherwise it will damage the machine and cause safety accidents. |

3. YLJ01 Large Manual Hydraulic Press

| 3.1 Parameters Table | ||

| Model | YLJ01-100T (4 Columns) | YLJ01-150T (4 Columns) |

| Pressure Range | 0~100 tons | 0~150 tons |

| Pressure Range | 0~39.3Mpa | 0~47.8Mpa |

| Piston Diameter | 180mm | 200mm |

| Maximum Piston Stroke | 50mm | 50mm |

| Workspace | 220×220×280mm | 250×250×320mm |

| Pressure Stability | ≤1Mpa/5min | ≤1Mpa/5min |

| Weight | 220kg | 310kg |

| Exterior Size | 480×300×840mm | 560×425×950mm |

| Product Image |  |  |

| 3.2 Pressure Conversion Table | |||||||||||

YLJ01-100T (4 Columns) | Cylinder Pressure (T) | 12.7 | 25.4 | 38.1 | 50.9 | 76.3 | 89 | 100 | / | / | / |

Indication on the pressure gauge (Mpa) | 5 | 10 | 15 | 20 | 25 | 30 | 39.3 | / | / | / | |

YLJ01-150T (4 Columns) | Cylinder Pressure (T) | 15.7 | 31.4 | 47.1 | 62.8 | 78.5 | 94.2 | 109.9 | 123.4 | 141.3 | 150 |

Indication on the pressure gauge (Mpa) | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 39.3 | 45 | 47.8 | |

| 3.3 Instrument structure (Illustration 3.1) | |||

| No. | Name | No. | Name |

| 1 | Upper | 9 | Oil-drainng valve |

| 2 | Screw | 10 | Pressure put A |

| 3 | Master cylinder | 11 | Pressure put B |

| 4 | Main board | 12 | Air release screw |

| 5 | Pressure gauge | 13 | Column |

| 6 | Vice board | 14 | Nut |

| 7 | High pressure valve | 15 | Hand wheel |

| 8 | Low pressure valve | 16 | Service screw (back side) |

YLJ01-100T (4 Columns) |

YLJ01-150T (4 Columns) | ||

[Procedure (See illustration 3.1)]

(1) Release the top vent seal srew 12 and the service screw 16, loosen the discharge valve wheel counterclockwise , swing the fast composite oil pump A and high pressure oil pump B handle 2~3 each to make the oil drcuit system work smoothly.

(2) Slowly press the workbench to the lowest part with the screw , and then tighten the screw.

(3) Place the mold or pressed items on the workbench and pre - tighten with wire bars.

(4) Turn tightly on the oil release valve hand wheel 9 dockwise and dose the protective door.

(5) First swing the fast composite pump A to about 14MPa, and then use the high pressure pump 8 to the required pressure.

(6) After the pressing , loosen the oil release valve hand wheel counterclockwise and remove the mold or the pressure item.

[The scope of application]

The instrument is mainly used in samples that require large pressure to form , such as ceramics , metal powder and other large size molds .

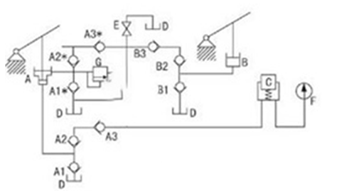

[Principle of Oil Channel (See Illustration 3.2)]

When the boost is required , first close the discharge valve E , shake the fast composite piston pump A to make the composite pump , small pump from the cylinder Dthrough check valve A1, A1*, and then through the check valve A2*, A3*, A3 into A2, working cylinder C, and show in the pressure gauge F, the large pump in more than 2 MPa through reverse valve G, small pump to about 14 MPa to high pressure pump B, oil into cylinder C through check valves B1, B2, B3, until the required pressure .

Note: do not exceed the maximum pressure of machine set (40 MPa or 48 MPa)

Illustration 3.2: YLJ01 Large Manual Hydraulic Press Principle of Oil Channel

[Notice]

1.before use must first loosen deflated oil cylinder screw screws 16 12 and maintenance, and loose open play two empty plunger valve conditions, make the system work normally.

2.before each use and use, should be pressed workbench use screw to the bottom.

3.to keep the oil clean, especially the size of the piston sliding, screw to lubrication on a regular basis.

4.there is any leakage and maintenance, to timely supply pressure oil, make it reach the top within 100 mm from the tin of oil, oil pressure was 46#clean the oil.

5.check the pressure value, overpressure must not be allowed to use, otherwise the risk will happen.

6.large piston 6 not more than 50 mm.

| 3.4 Troubleshooting | ||

| Malfunction | Reasons | Solution |

| No Pressure | 1. The oil leaks from the screw. 2. The drain valve is not tightend. | 1. Replace the gasket and solve the leak. 2. screw down. 3. Press the large piston to the bottom. |

Off the pressure | 1. The oil leaks from the screw. 2. The outlet valve is not strict or there are foreign bodies. 3. There is residual gas in piston3. | 1. Find out the small oil leakage and eliminate it 2. Close the maintenance screw, and unscrew the oil discharge valve stem. Connect the iron rod with a magnet to suck out the steel ball. 3. Unscrew the top of the piston, tighten the handwheel of the oil release valve, and press until the liquid oil overflows. |

| Machine deformation | 1. The pressure is high and the column nut is loose due to. 2. Exceed allowable pressure. | 1. Tighten the column or the column nut. 2. Reduce the use pressure, otherwise it will damage the machine and cause safety accidents. |

For international orders, please ask us for quotes via

Email: contact@scimaterials.cn

Tel: +86 153-5789-9751

Clik here to put quick orders on our Alibaba shop

| YLJ Manual Hydraulic Press (01 Series) | |||

| Product Code | Product Description | Product price and specification | Stock Status |

| 2902001-1 | YLJ01-10T (2 Columns) | Ask for quote | Ask for quote |

| 2902001-2 | YLJ01-15T (2 Columns) | Ask for quote | Ask for quote |

| 2902001-3 | YLJ01-15T (4 Columns) | Ask for quote | Ask for quote |

| 2902001-4 | YLJ01-24T (4 Columns) | Ask for quote | Ask for quote |

| 2902001-5 | YLJ01-30T (4 Columns) | Ask for quote | Ask for quote |

| 2902001-6 | YLJ01-40T (4 Columns) | Ask for quote | Ask for quote |

| 2902001-7 | YLJ01-60T (4 Columns) | Ask for quote | Ask for quote |

| 2902001-8 | YLJ01-100T (4 Columns) | Ask for quote | Ask for quote |

| 2902001-9 | YLJ01-150T (4 Columns) | Ask for quote | Ask for quote |

| SCI Materials Hub is Committed to Offerig The Best Price & Customer Services! | |||

- The price listed above is in U.S. dollars

Worldwide shipping via DHL, SF-Express, FedEx, TNT & other requested carriers.

Payments via Bank Transfer, Paypal, Credit card (via Alibaba), Alipay, Wechat-pay are accepted.

Please contact us for larger quantities or becoming our distributors.

Partial references citing our materials (from Google Scholar)

Carbon Dioxide Reduction

1. ACS Nano Strain Relaxation in Metal Alloy Catalysts Steers the Product Selectivity of Electrocatalytic CO2 Reduction

The bipolar membrane (Fumasep FBM) in this paper was purchased from SCI Materials Hub, which was used in rechargeable Zn-CO2 battery tests. The authors reported a strain relaxation strategy to determine lattice strains in bimetal MNi alloys (M = Pd, Ag, and Au) and realized an outstanding CO2-to-CO Faradaic efficiency of 96.6% with outstanding activity and durability toward a Zn-CO2 battery.

2. Front. Chem. Boosting Electrochemical Carbon Dioxide Reduction on Atomically Dispersed Nickel Catalyst

In this paper, Vulcan XC-72R was purchased from SCI Materials Hub. Vulcan XC 72R carbon is the most common catalyst support used in the anode and cathode electrodes of Polymer Electrolyte Membrane Fuel Cells (PEMFC), Direct Methanol Fuel Cells (DMFC), Alkaline Fuel Cells (AFC), Microbial Fuel Cells (MFC), Phosphoric Acid Fuel Cells (PAFC), and many more!

3. Adv. Mater. Partially Nitrided Ni Nanoclusters Achieve Energy-Efficient Electrocatalytic CO2 Reduction to CO at Ultralow Overpotential

An AEM membrane (Sustainion X37-50 Grade RT, purchased from SCI Materials Hub) was activated in 1 M KOH for 24 h, washed with ultra-purity water prior to use.

4. Adv. Funct. Mater. Nanoconfined Molecular Catalysts in Integrated Gas Diffusion Electrodes for High-Current-Density CO2 Electroreduction

In this paper (Supporting Information), an anion exchanged membrane (Fumasep FAB-PK-130 obtained from SCI Materials Hub (www.scimaterials.cn)) was used to separate the catholyte and anolyte chambers.

SCI Materials Hub: we also recommend our Fumasep FAB-PK-75 for the use in a flow cell.

5. Appl. Catal. B Efficient utilization of nickel single atoms for CO2 electroreduction by constructing 3D interconnected nitrogen-doped carbon tube network

In this paper, the Nafion 117 membrane was obtained from SCI Materials Hub.

In this paper, Proton exchange membrane (Nafion 117), Nafion D520, and Toray 060 carbon paper were purchased from SCI Materials Hub.

7. National Science Review Confinement of ionomer for electrocatalytic CO2 reduction reaction via efficient mass transfer pathways

An anion exchange membrane (PiperION-A15-HCO3) was obtained from SCI Materials Hub.

8. Catalysis Communications Facilitating CO2 electroreduction to C2H4 through facile regulating {100} & {111} grain boundary of Cu2O

Carbon paper (TGPH060), membrane solution (Nafion D520), and ionic membrane (Nafion N117) were obtained from Wuhu Eryi Material Technology Co., Ltd (a company under SCI Materials Hub).

Batteries

1. J. Mater. Chem. A Blocking polysulfides with a Janus Fe3C/N-CNF@RGO electrode via physiochemical confinement and catalytic conversion for high-performance lithium–sulfur batteries

Graphene oxide (GO) in this paper was obtained from SCI Materials Hub. The authors introduced a Janus Fe3C/N-CNF@RGO electrode consisting of 1D Fe3C decorated N-doped carbon nanofibers (Fe3C/N-CNFs) side and 2D reduced graphene oxide (RGO) side as the free-standing carrier of Li2S6 catholyte to improve the overall electrochemical performance of Li-S batteries.

This paper used more than 10 kinds of materials from SCI Materials Hub and the authors gave detailed properity comparsion.

The commercial IEMs of Fumasep FAB-PK-130 and Nafion N117 were obtained from SCI Materials Hub.

Gas diffusion layers of GDL340 (CeTech) and SGL39BC (Sigracet) and Nafion dispersion (Nafion D520) were obtained from SCI Materials Hub.

Zn foil (100 mm thickness) and Zn powder were obtained from the SCI Materials Hub.

Commercial 20% Pt/C, 40% Pt/C and IrO2 catalysts were also obtained from SCI Materials Hub.

3. Journal of Energy Chemistry Vanadium oxide nanospheres encapsulated in N-doped carbon nanofibers with morphology and defect dual-engineering toward advanced aqueous zinc-ion batteries

In this paper, carbon cloth (W0S1011) was obtained from SCI Materials Hub. The flexible carbon cloth matrix guaranteed the stabilization of the electrode and improved the conductivity of the cathode.

4. Energy Storage Materials Defect-abundant commercializable 3D carbon papers for fabricating composite Li anode with high loading and long life

The 3D carbon paper (TGPH060 raw paper) were purchased from SCI Materials Hub.

5. Nanomaterials A Stable Rechargeable Aqueous Zn–Air Battery Enabled by Heterogeneous MoS2 Cathode Catalysts

Nafion D520 (5 wt%), and carbon paper (GDL340) were received from SCI-Materials-Hub.

Carbon cloth (W0S1011) and other electrochemical consumables required for air cathode were provided by SCI Materials Hub.

Oxygen Reduction Reaction

1. J. Chem. Eng. Superior Efficiency Hydrogen Peroxide Production in Acidic Media through Epoxy Group Adjacent to Co-O/C Active Centers on Carbon Black

In this paper, Vulcan XC 72 carbon black, ion membrane (Nafion N115, 127 μL), Nafion solution (D520, 5 wt%), and carbon paper (AvCarb GDS 2230 and Spectracarb 2050A-1050) were purchased from SCI Materials Hub.

2. Journal of Colloid and Interface Science Gaining insight into the impact of electronic property and interface electrostatic field on ORR kinetics in alloy engineering via theoretical prognostication and experimental validation

The 20 wt% Pt3M (M = Cr, Co, Cu, Pd, Sn, and Ir) were purchased from SCI Materials Hub. This work places emphasis on the kinetics of the ORR concerning Pt3M (M = Cr, Co, Cu, Pd, Sn, and Ir) catalysts, and integrates theoretical prognostication and experimental validation to illuminate the fundamental principles of alloy engineering.

Water Electrolysis

1. International Journal of Hydrogen Energy Gold as an efficient hydrogen isotope separation catalyst in proton exchange membrane water electrolysis

The cathodic catalysts of Pt/C (20 wt%, 2–3 nm) and Au/C (20 wt%, 4–5 nm) were purchased from SCI Materials Hub.

2. Small Science Silver Compositing Boosts Water Electrolysis Activity and Durability of RuO2 in a Proton-Exchange-Membrane Water Electrolyzer

Two fiber felts (0.35 mm thickness, SCI Materials Hub) were used as the porous transport layers at both the cathode and the anode.

3. Advanced Functional Materials Hierarchical Crystalline/Amorphous Heterostructure MoNi/NiMoOx for Electrochemical Hydrogen Evolution with Industry-Level Activity and Stability

Anion-exchange membrane (FAA-3-PK-130) was obtained from SCI Materials Hub website.

Fuel Cells

1. Polymer Sub-two-micron ultrathin proton exchange membrane with reinforced mechanical strength

Gas diffusion electrode (60% Pt/C, Carbon paper) was purchased from SCI Materials Hub.

Characterization

1. Chemical Engineering Journal Electrochemical reconstitution of Prussian blue analogue for coupling furfural electro-oxidation with photo-assisted hydrogen evolution reaction

An Au nanoparticle film was deposited on the total reflecting plane of a single reflection ATR crystal (SCI Materials Hub, Wuhu, China) via sputter coater.

|

We Provide A Broad Range of Materials, Instruments & Solutions in Advanced Science and Technologies | About Us |